Product description

The spiral brush is named from its surface shape. In fact, the production procedure is, brush wire for cleaning is evenly placed on a flat galvanized iron which is then symmetrically and tightly folded, and then crimp and cut the folded galvanized iron according to the length and outer diameter of the inside shaft required by the customers

Spiral Brushes can be divided as Outward Spiral Brush Shape and Inward Spiral Brush Shape. It is mainly used in coating, steel (steel plate pretreatment, steel plate galvanizing, steel plate color coating), glass cleaning industries, bleaching and dyeing printing and dyeing industry ,surface treatment of steel plates, copper substrates, galvanized plates, and aluminum plates.etc.

Hightlights

-Perfect ring shape

-No bristle falling off

-Acid and alkali resistant

-Food grade

Area of application

Spiral Brushes material determines the use.

1. Metal wire spring brushes are mainly used in steel, painting and other industries.

2, nylon wire spring brush are mainly used in cleaning, polishing of furniture wood, rust removal of color coated rolls and other industries.

Application range: Used for degreasing, rust removal, polishing, cleaning, etc.; stainless steel wire brush roller is used for rust removal, deburring or special treatment of the surface of the steel plate into a stripe base effect.

Technical data

Filament Material: Brass coated wire steel, nylon, steel wire, brass wire,stainless steel wire

Base: 3*3mm, 4*4mm, 5*5mm, 8*8mm, 10*10mm

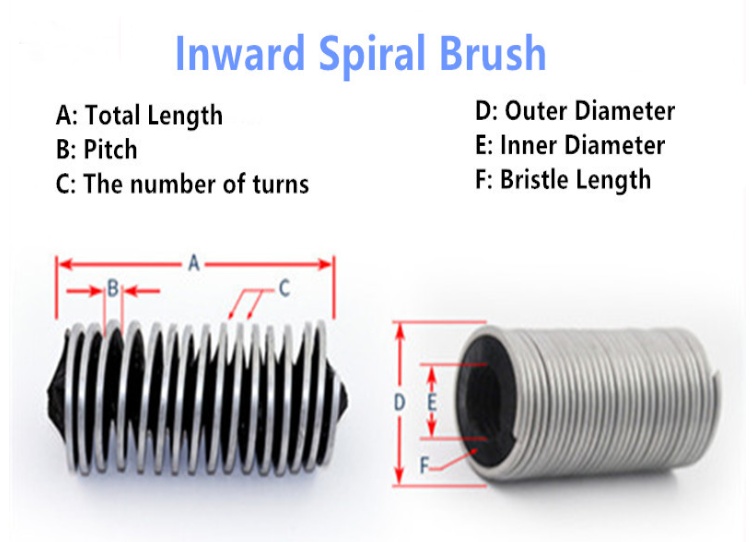

Inside Spiral Coil Brushes is made from the strip brush. If you need to Purchase the Inside Spiral Brushes , please offer us your specification as below require: